RA Power Solutions was approached by a leading Cement manufacturing Plant based in Nepal regarding the failure of their Crankshaft of Wartsila Diesel Generator model no. WARTSILA VASA 12V32 LN.

The Cement Plant in Nepal is having multiple numbers of Wartsila diesel generating sets model VASA 12V32 LN, Wartsila 18 V 32, and Wartsila 12 V32. The one number crankpin got damaged due to seizure of the bearing of Wartsila Diesel generating set Vasa 12 V32 LN.

Wartsila Diesel Generator Crankshaft main Observations:

- On inspection of all the crankpins visually the Bearing of crankpin no. 3 was observed damaged and bearing material was found in the oil sump.

- On removal of connecting Rods from crank pin no 3. A & B bank, it was found that the bearing was badly struck to the crankpin diameter and it was a case of bearing failure.

- The Bearing was removed from the crankpin and on visual inspection, it was observed that bearing material was embedded on the crankpin. The radius fillet of both sides of the crankpin was found damaged and the profile of the radius fillet was distorted.

- After cleaning and little polishing of crankpin to remove the bearing material the crack detection test by MPI method was undertaken. No crack was observed.

- The hardness was also checked and it was observed in the range of 600 HB in a scattered formation which is considered to be on the higher side.

- The crankpin was subject to dimensional inspection and the following dimensions were observed.

- Minimum diameter observed- 269.02 mm

- Maximum diameter observed- 270.00 mm

Against the standard diameter of 270 mm, the ovality of 0.98 mm was observed which is considered to be very much on a higher side.

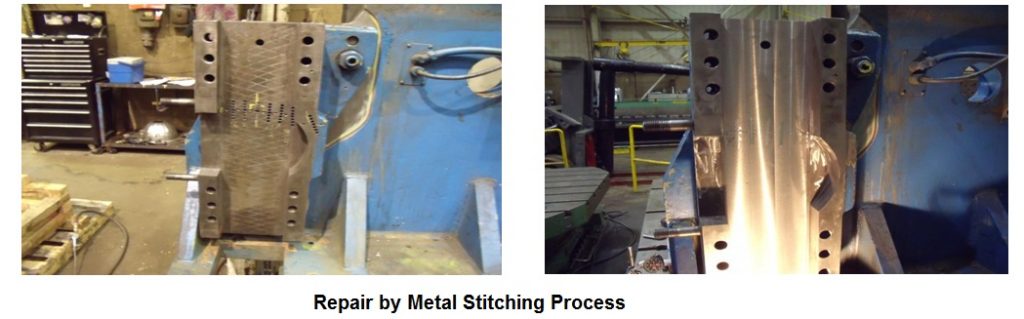

Achievement by RA Power Solutions in successful Repair of Wartsila Crankshaft 12V32 LN:

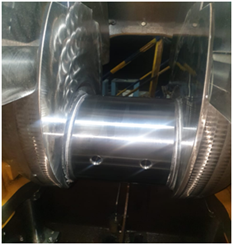

The successful repair of damaged crank pin no. 3 of Wartsila Crankshaft 12V32 in a short time of 79 hrs is an achievement, the grinding of crankpin was undertaken nonstop on 24 hours basis by a team of three technicians of RA Power Solutions.

RA Power technicians have undertaken the grinding of crankpin having a standard diameter of 270 mm. Due to serious damage of crankpin, it is to be undersized by 2.0 mm.

The Wartsila Diesel Generator set has been assembled and is in operation.

We have been regularly undertaking crankshaft repair of Wartsila Diesel engine Model No. 12V32, Wartsila 46, Wartsila 43, Wartsila 12V26, Wartsila 12V20 and can undertake grinding of crankshafts up to 700 mm diameter.

For more details of the crank pin grinding machine, wartsila crankshaft repair, and wartsila diesel generator crankshaft email us on info@rapowersolutions.com, rajshahani@rapowersolutions.com, call at +91 9582647131,+91 9810012383.