Sulzer model 6RTA Engine was reported damaged on high seas near Mombasa on transit to Sri Lanka. On investigation, it was observed that the connecting rod bolts got sheared damaging the lower and upper engine block and three crankpins of the Crankshaft.

A team of RA Power Solutions technicians having experience in undertaking insitu crankpin machining and a team undertaking repair of crack and damaged engine block by metal stitching and metal locking process was deputed on board a vessel within a short notice as all of them have a seamen passport.

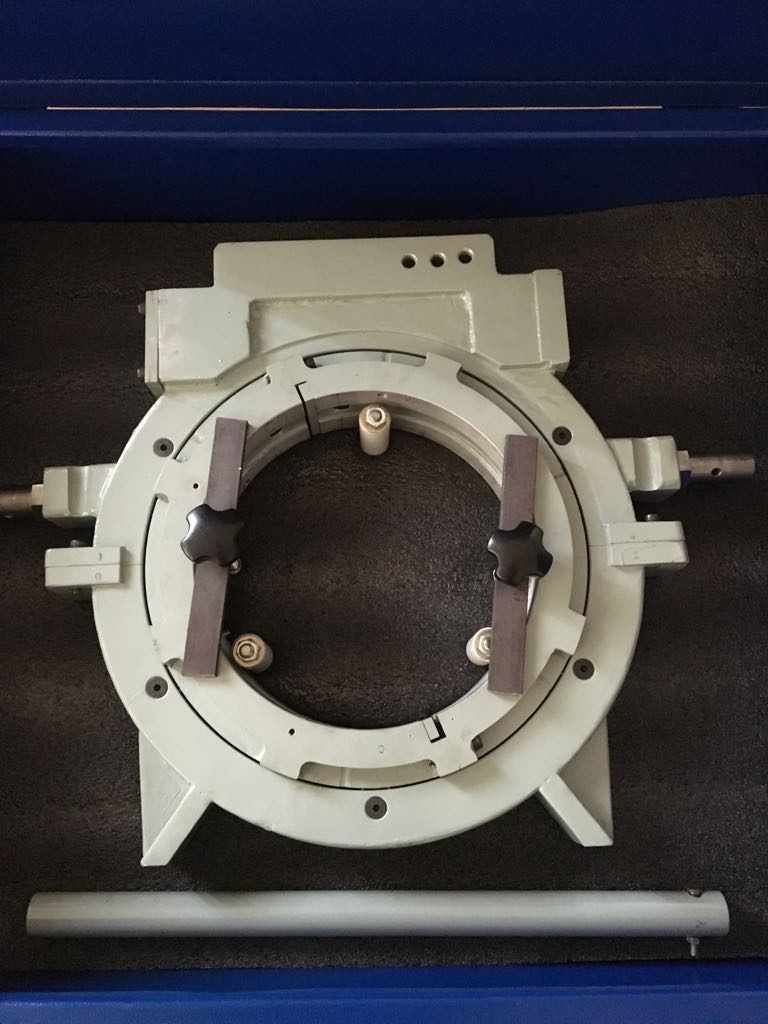

On preliminary examination, multiple cracks on the upper and lower crack cases of the engine block were observed measuring in totality 2900 mm in terms of length. Three crankpins were damaged developing taper and ovality exceeding more than 1 mm. RA Power Solutions team of technicians worked non-stop and executed the repair of crankpins by an onsite crankshaft grinding machine. All pins were undersized to 1.5 mm due to the damage.

The engine block cracks were repaired by metal locking and metal stitching process. The complete job was executed within 68 hours. The hard work, knowledge, experience, and sincerity of technicians have been very much appreciated by the owners. This achievement was possible due to RA Power Solutions having the latest design of equipment, and experienced technicians having Indian CDC.

For more information on crankpin machining, metal locking and metal stitching process please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.