The Wartsila 4L20 crankshaft was repaired by RA Power Solutions technicians on board a vessel while sailing. The vessel is owned by a reputed shipping company based in kuwait. Due to the serious accident the crankshaft was removed from the engine block as the crankcase of Wartsila 4L20 was also badly damaged beyond repair.

The main dimensions of the crankshaft of Wartsila 4L20 are as follows:

| S. NO | Crankshaft Details | |

| 1. | Engine Make | Wartsila |

| 2. | Engine Model | 4L20 |

| 3. | Crank pin Diameter Standard | 180 mm |

| 4. | Crankpin Bearing Width | 71 mm |

| 5. | Main journal diameter | 210 mm |

| 6. | Place of execution of crankshaft repair | Sailing from Paradip Port to Ennore Port India |

Action taken by RA Power Solutions technicians to repair the Wartsila 4L20 Crankshaft

- On arrival our technicians observed that the damaged crankshaft was lying on the floor. A design of v block was made and V block was manufactured on the vessel. This was done to do the inspection & grinding of the crankshaft as it was aleady removed from the engine block.

RA Power has a tooling by which crankpin grinding can be done without removing the crankshaft from the block

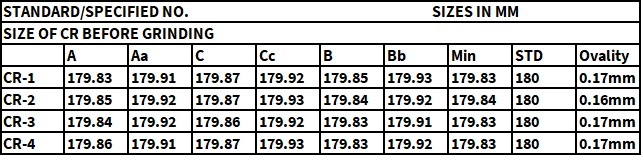

- All four crankpins were inspected. The maximum ovality of 0.17 mm was observed.

Inspection report is pasted below:

- Uneven surface, bearings line marks and pitting marks were observed on all crankpins.

- All main journals were also dimensionally checked and were observed to be within limits. The standard diameter of the main journal is 210 mm.

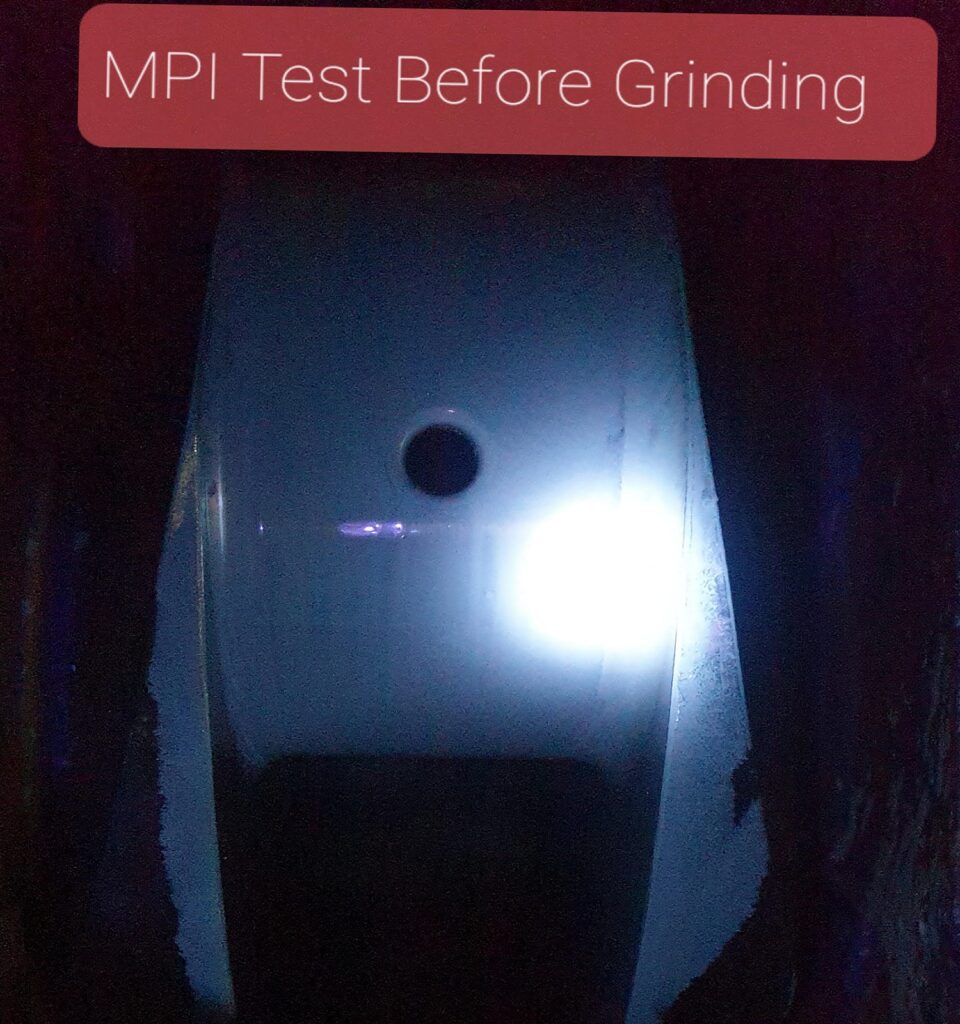

- As a matter of routine hardness test, crack detection test, surface finish test etc was done and observed within limits.

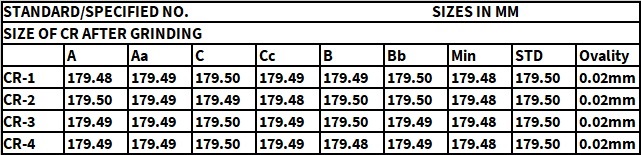

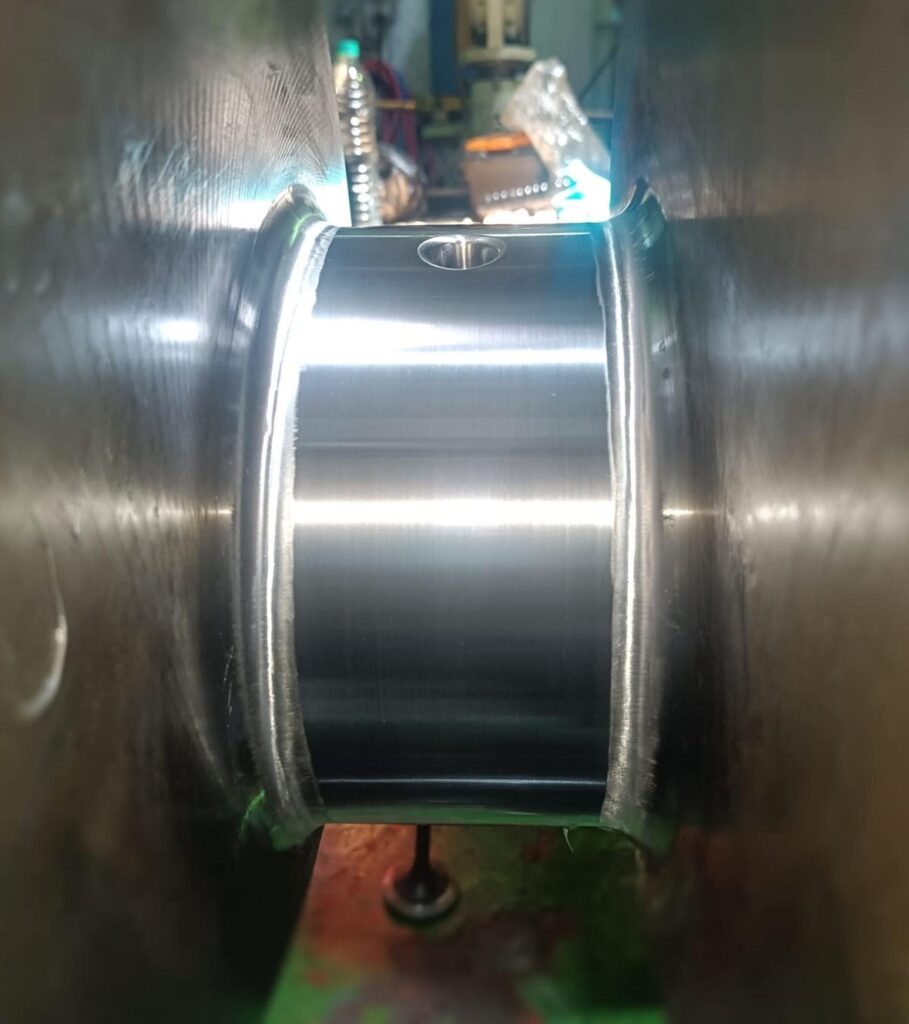

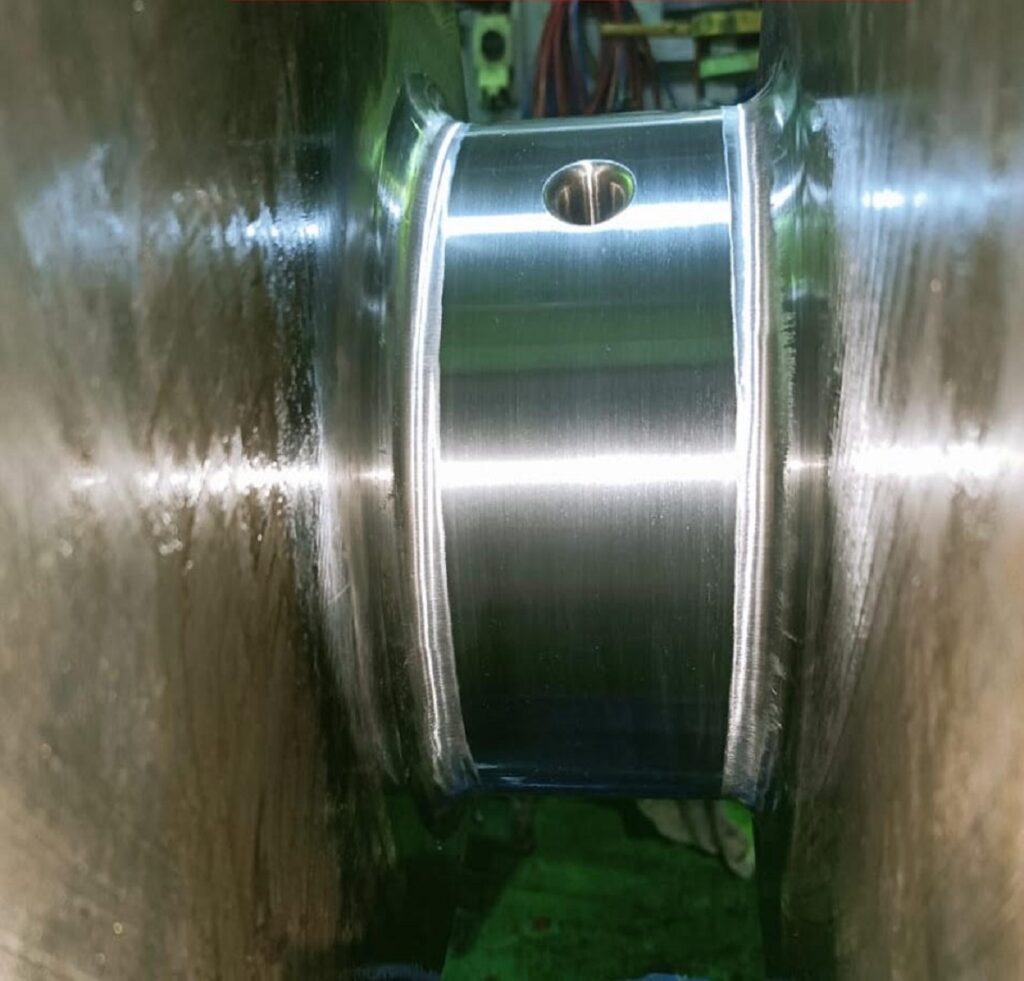

- The grinding of damaged crankpins was done and all the crankpin were undersized by 0.50 mm only. The final size of the crankpin was maintained between 179.48 to 179.50 mm.

The final diameter maintained after grinding of crankpins is pasted below:

The above job was done while sailing of the vessel from Paradip port to Ennore port India and there was no need of stopping the vessel.

We have been regularly executing the repairs in Madagascar, Oman, Qatar, Philippines, Bahrain, Srilanka, Bangladesh, Myanmar, Turkey, Nigeria, Greece, Saudi Arabia, UK, Dubai, Malta, Cyprus, Singapore, Malaysia, Colombia, Indonesia, Hong Kong, Spain, Netherlands, Dubai, Portugal, Estonia, Morocco, Belgium, Vietnam, Canada, Jordan, Libya, Kuwait, Egypt, Morocco, Yemen, Bahrain, Tunisia, Sudan, Oman, Algeria, UAE, Iraq.

For more informationon Wartsila 4L20 Crankshaft Repair, contact us on rajshahani@rapowersolutions.com, info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.