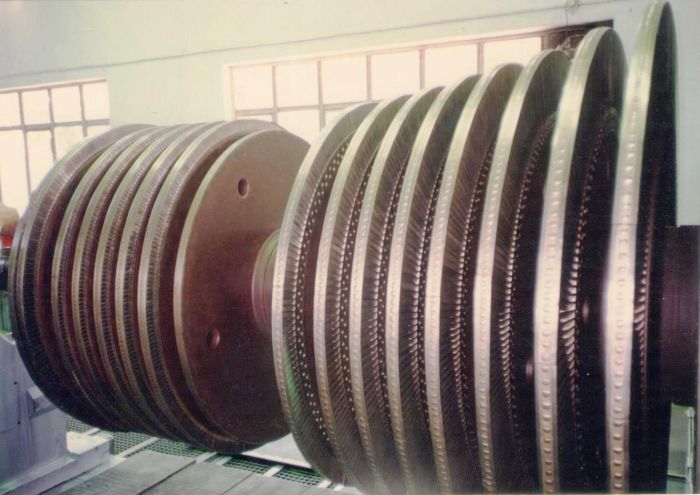

A Sulzer main engine Sulzer Z 40/48 aboard a container vessel faced serious damage to the crankshaft due to failure of the Governor, this resulted in damage to crankpins.

The major technical details of Sulzer Z 40/48 crankshaft are given below:

| S. No. | Crankshaft Details | |

| 1. | Engine Make | Sulzer |

| 2. | Engine Model | Z 40/48 |

| 3. | Crankpin Diameter Standard | 330 mm |

| 4. | Crankpin Bearing Width | 132 mm |

| 5. | Place of execution of crankshaft repair | Port of Las Calderas Bani in Dominican Republic |

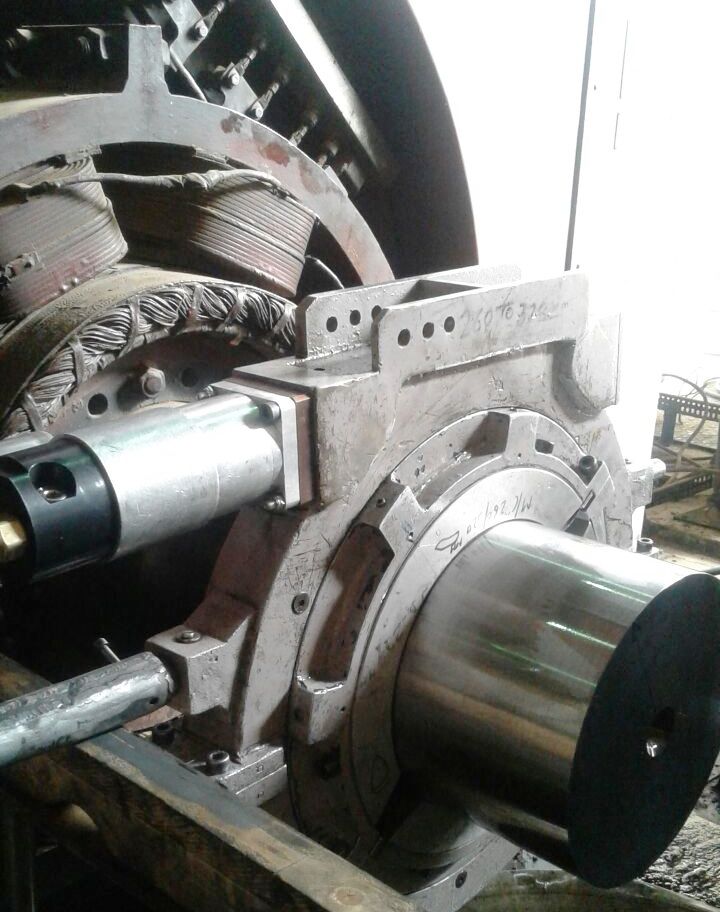

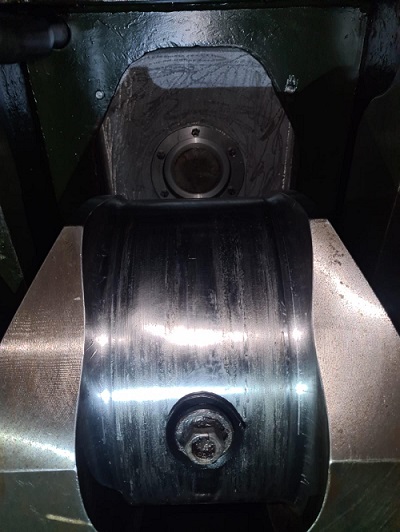

The inspection of the Sulzer crankshaft was done by our technicians and the following main observations were reported.

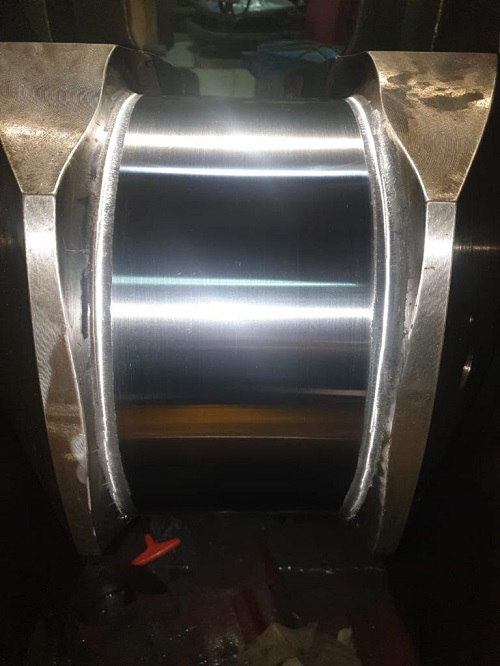

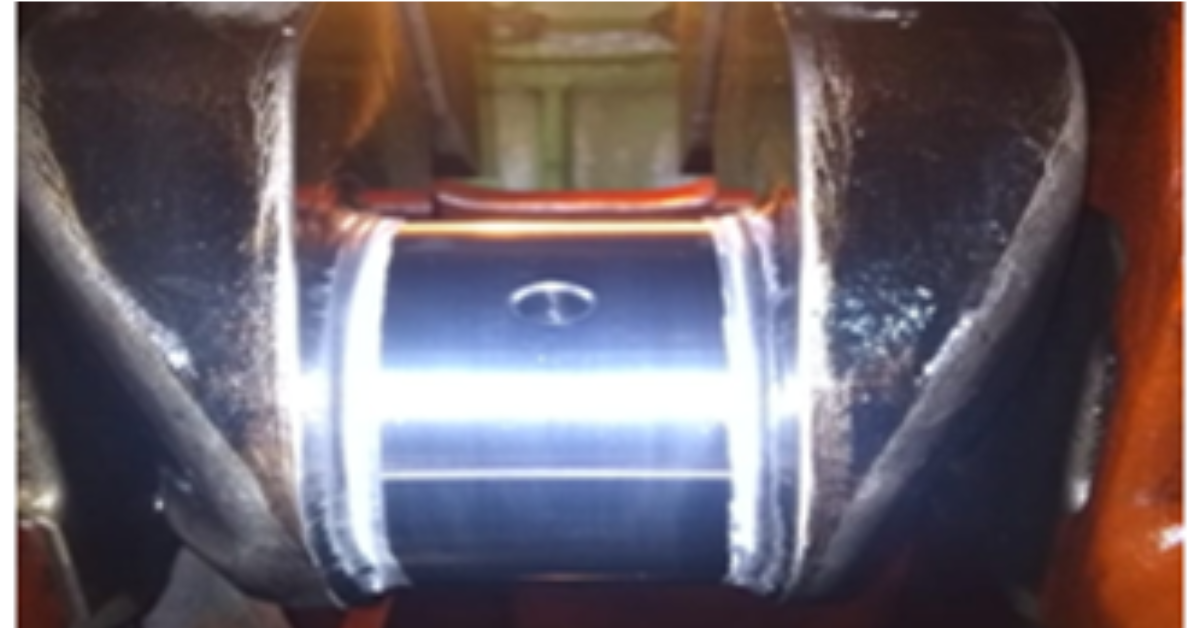

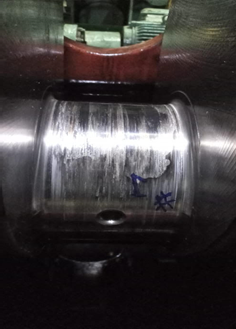

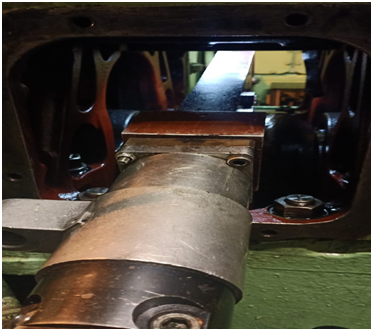

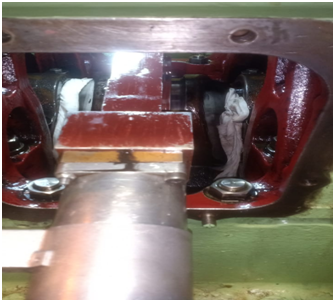

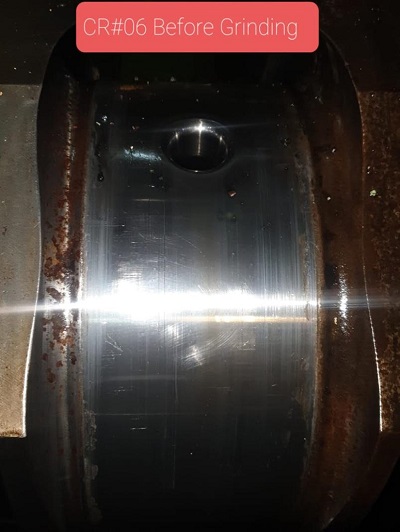

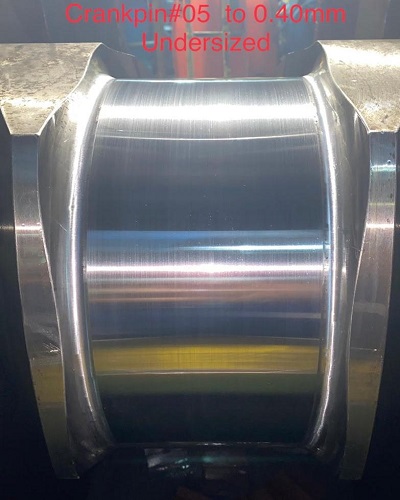

- On removal of the connecting rod from all the six crankpins the crankpin bearings were observed badly damaged. There were deep scoring marks and localized damage on the crankpin.

- The hardness and crack detection was done and they were observed to be within limits.

- Deflection readings were within the parameters stipulated in the manual.

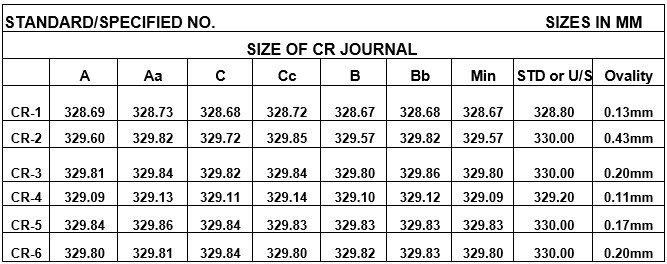

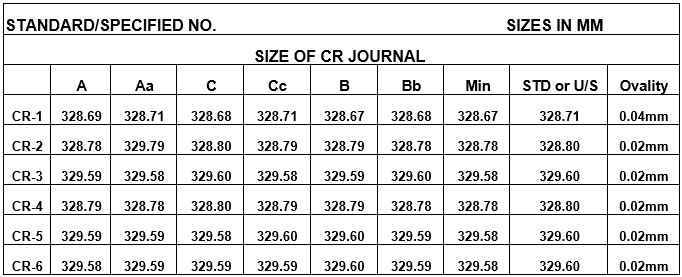

- The crankpins dimensional were checked and ovality as per following table was observed.

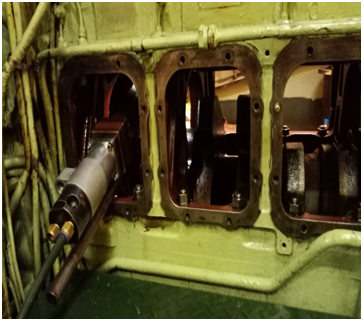

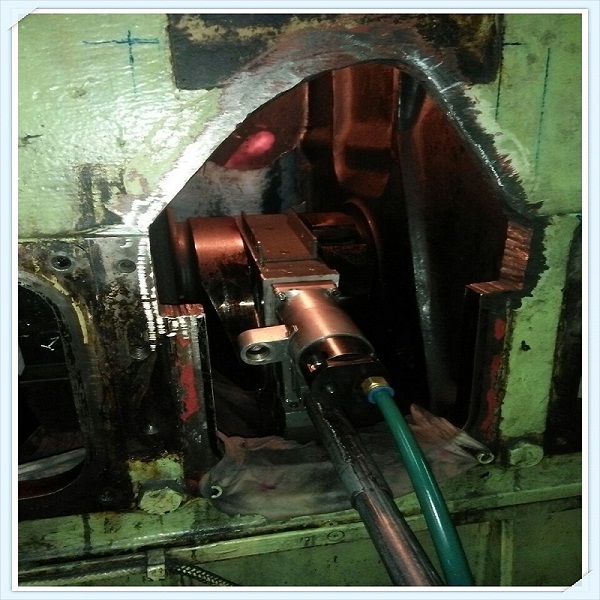

Action taken by RA Power Solutions for successfully repair of crankshaft Sulzer Z 40/48

- The ovality, deep scoring marks and local damage was observed on all crankpins, further the ovality ranging from 0.11 mm to 0.43 mm was observed as per the dimensional chart pasted above.

- In this situation client’s management was consulted and a presentation was made on the damage to the crankshaft and the remedial action proposed by RA Power Solutions.

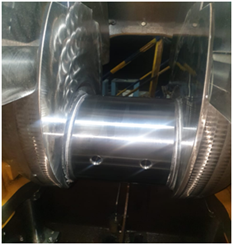

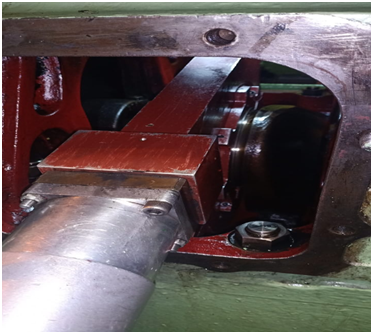

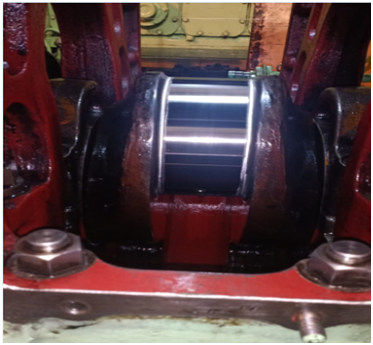

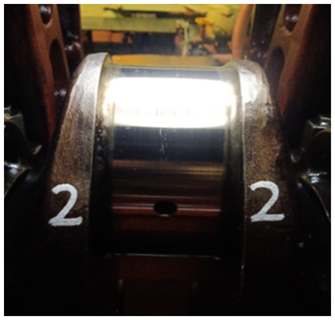

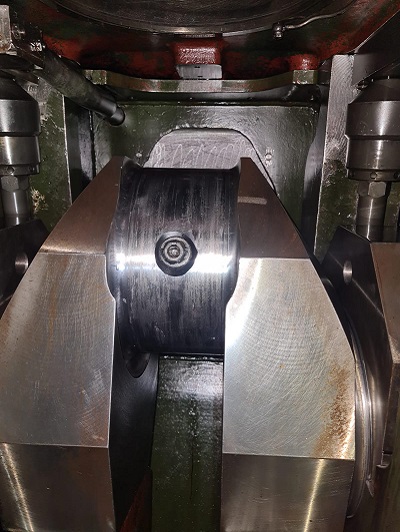

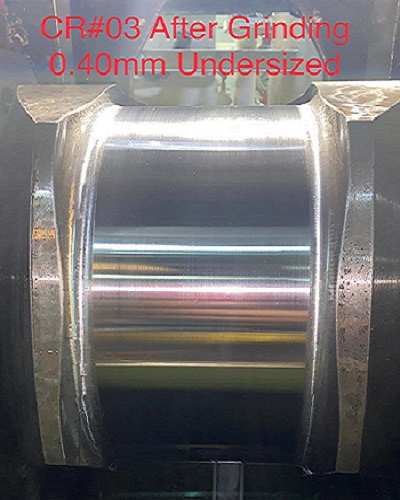

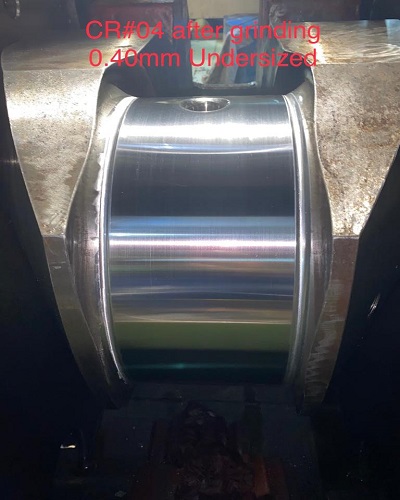

- All the crankpins were undersized as per the chart below except crankpin no 01 which was only polished:

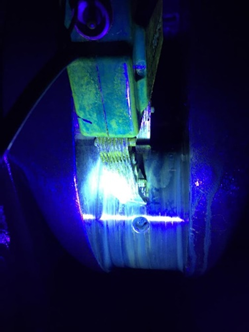

- The radius fillet of two crankpins which were damaged due to the accident was also repaired.

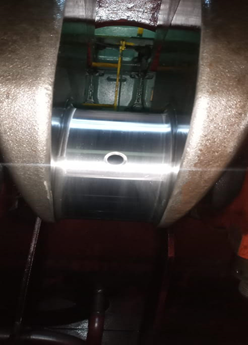

- After repair technicians again checked all the parameters and were found within limits.

Sulzer Model Z 40/48 crankpin repair results

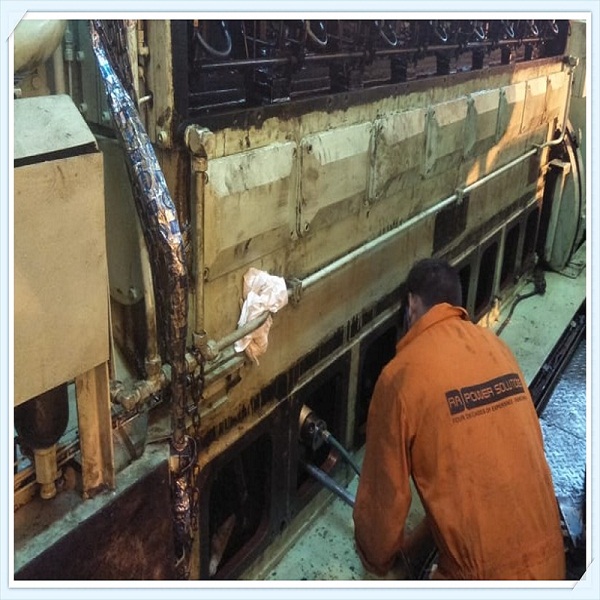

RA Power Solutions experienced technicians repaired the crankshaft successfully within the tolerance limits specified in the manual and then re- install the crankshaft to full rated capacity of the load.

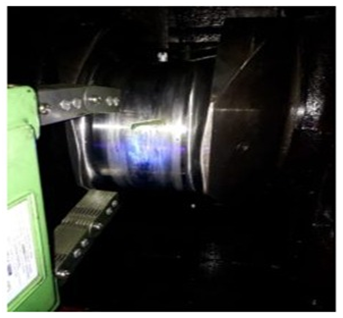

By undertaking the repairs of the crankshaft onsite without removing it from the engine block, clients save the down time and also the cost of removing it from the block and sending it to the workshop.

RA Power Solutions is ISO 9001:2015 (Quality Management System) & ISO 14001:2015 (Environmental Management System) certified approved company and extends crankshaft repair services all over the world. We can move our team of technicians and equipment anywhere in the world within 24 hours of first information.

We have been regularly executing on-site crankshaft repairs and crankshaft grinding in Dubai, Oman, Saudi Arabia, Qatar, Abu Dhabi, Sharjah, Ajman, Umm Al-Quwain, and Fujairah, Bahrain, Kuwait, Iraq, Antigua and Barbuda, Belize, Dominica, Dominican Republic, Grenada, Guyana, Haiti, Jamaica, Saint Kitts and Nevis, Saint Lucia, Saint Vincent and the Grenadines, Trinidad, and Tobago, etc.

For more details of the Repair of engine, Engine Sulzer, please email us on raj.shahani@rapowersolutions.com, info@rapowersolutions.com or Call +91 9582647131, +91 9810012383.