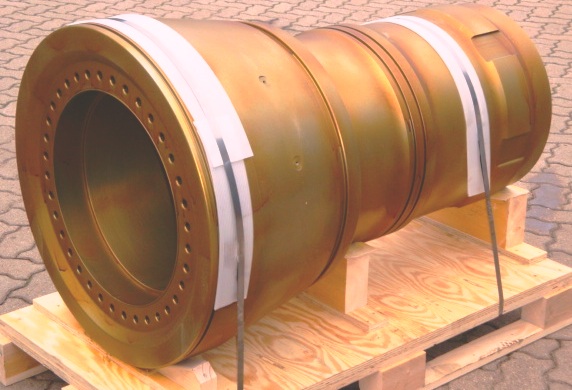

Cylinder liners are integral part of diesel engine. RA Power Solutions Pvt. Ltd. manufactures cylinder liners having bore size up to 650 mm and length of 1500 mm. The metallurgy of casting is maintained strictly as per the requirement i.e. RPM, load characteristics and design features. The cylinder liners are centrifugally cast in a modern, well equipped foundry. After casting of cylinder liners, each cylinder liner passes through stringent quality control procedures. Presence of hairline cracks is checked by magnetic particle inspection (MPI) and is conducted by a trained and experienced technician.

The cylinder liner casting is visually checked for the presence of blow holes, porosity, or any abnormality during the casting of cylinder liner.

The cylinder liners are initially rough machined in-house by the latest design of machine and tools installed at our works. The final machining is undertaken on DRDO-equipped machines which are capable to maintain close tolerances as per the manufacturer’s requirement. The honing operation of cylinder liners is undertaken on world famous Chris Marine machines imported from Sweden.

The cylinder liners are finally checked for all dimensions and reports are prepared. We maintain large stock of cylinder liners for popular makes of diesel engine which includes following: Wartsila, Mak,Deutz, Bergen, Niigata, Himsen, Allen, Stork, Fiat, MWM, Hanshin, Caterpillar, etc.

All the cylinder liners supplied by us are guaranteed for satisfactory performance and are priced considerably lower than the cylinder liners manufactured by other manufacturers.

RA Power Solutions Pvt. Ltd also supplies reconditioned cylinder liners which are re-honed in-house and have minimum wear and tear. We also manufacture cylinder liners as per the customer’s drawing or sample, in case it does not fall in our present range of manufacturing.

You can write us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383..